?

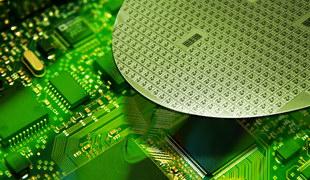

Wafers Nikon Metrology

At the heart of almost every electronic product are wafers, thin slices of semiconductor materials on which microcircuits are constructed through the diffusion and deposition of various substances. Representing one of the most challenging areas of modern technology, the wafer industry has existed under the historical tenets that each generation of chip must be made thinner, more efficient and less costly.

Today wafer manufacturers are also facing increased pressure from consumers to get their latest products to market faster. Whereas previous generations of microchips were released every two or four years, today’s turnover times are counted in months, with many customers expecting new products each year. Although the move to nanoscale devices can help reduce the cost per function of each device, the design requirements of these high performance chips also present new technical challenges for the metrology used in their manufacture and inspection.

In this demanding environment, even the smallest deviation can have significant downstream impacts that can lead to millions of dollars in lost resources and market revenues. Manufacturers in this industry must always keep a close eye on production-related issues at the wafer’s edge as well as possible defects in the sub-micron range such as contaminating particles, open lines and shorts between lines. To achieve this, wafer inspection teams rely on transmitted and reflected light images (using white light or lasers) to identify surface defects early in the production process so that swift corrective measures can be taken.