Laser Gas Analyzer .LGA – 4500

Features and Benefits

- Fast response

- High accuracy, ppm level resolution

- No cross interference

- Online calibration, no zero drift

- Reliable in all harsh conditions: high temperature &

pressure, dust density, moisture and corrosion

- International ATEX certified

Application Areas

- All other applications where in-situ doesn’t fit due

to high pressure or dust density, limitation of stack

diameter or position.

- HCL, HF, NH3 , H2S emission monitoring

- Trace H2O in VCM Production

- Coal Injection Safety Control

- SCR NH3 Injection in Coal-fueled Plants

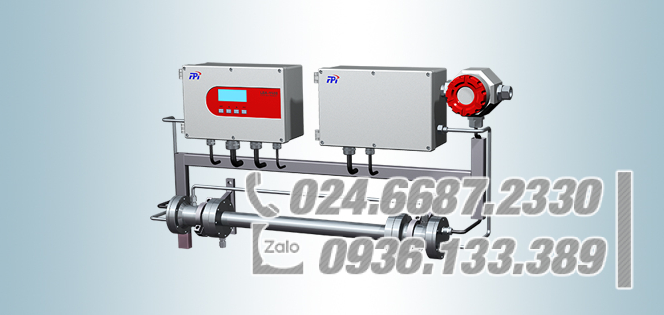

LGA Composition

Technical Data

Specifications

- Repeatability:≤±1%F.S.

- Linearity:≤±1%F.S.

- Span drift:≤±1%F.S/6 months

- Instrument response time:≤1s*

- Warm-up time:≤15min

- Gas cell temperature: -30℃ to +250℃

- Gas cell pressure: 0.5 to 3 bar abs.

- *Gas flow>1L/min, system response time: T90≤20s.

Input & Outputs

- Analog outputs: 2 outputs 4-20mA, max. load

750Ω,electrically isolated

- Communications: RS485(or Bluetooth, RS232

or GPRS )

- Relay outputs: 3 outputs 24V DC/1A

Operating Conditions

- Power supply: 200-240V AC/48-63Hz

- Power consumption:≤30W (no heat tracing)

- Operating temperature: -30℃ to +60℃

- Storage temperature: -40℃ to +80℃

- Purge gas: 0.3MPa nitrogen gas or instrument air

- Protection class: IP65

Approvals

- Laser class: class 1 conformant with IEC60825-1

- CE certified: conformant with 2004/108/EC