Main applications

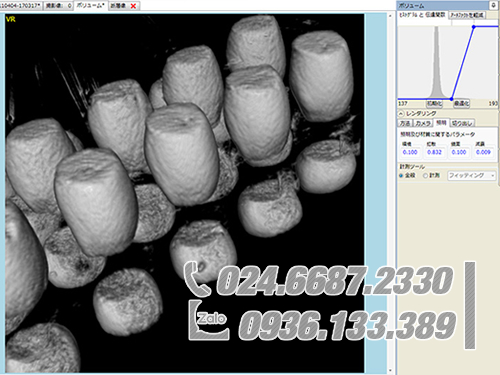

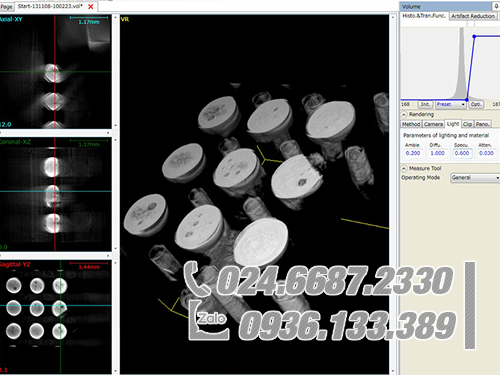

BGA void position, defect of small electronic parts.

Solder pole

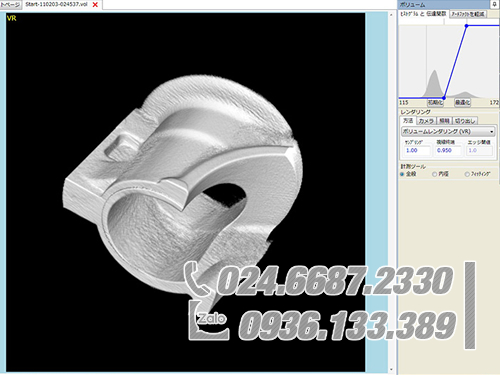

aluminum die cast

BGA

Constitution

| item | Classification | Contents |

|---|---|---|

| Work rotating part | Rotation mechanism | Adjustable turning axis angle by gonio stage |

| Rotary motor and driver included | ||

| Calibration jig/td> | Removable | |

| Work fixing jig | For board parts, small parts such as capacitors | |

| Personal computer | PC specification | Windows xp sp2;7 IntelCore2Duo;1.86GHZ,2Gib RAM |

| Network equipment | High speed hub for data transfer with inspection equipment PC | |

| Software for CT | Image reconstruction program and image display / rendering | CT reconstruction integrated software TomoShop |

| Rotating section control | Work rotation and image input software (manufactured by SOFTEX) |

specification

| item | Classification | Contents |

|---|---|---|

| Inspection work size | SMT · PCB board | 50×100×2mm |

| Small electronic components (capacitors, etc.) | φ5mm~10mm、h=5mm~20mm | |

| Maximum rotating mechanism weight | Approximately 100g | |

| Image composition time | Image Projection 400frame Image Projection 400 frame Number of integrations 16 |

About 3 minutes 20 seconds |

| Image Projection 900frame Number of integrations 16 |

About 7 minutes 30 seconds | |

| Image Projection 1200frame Number of integrations 16 |

About 11 minutes and 00 second | |

| Additional Conditions: Depends on case when using 1 million pixel X-ray camera | ||

| CT reconstruction / calculation function | XYZ 3 direction | CT reconstruction integrated software by TomoShop rendering function |

| Rotary axis correction function | Correction by TomoShop focusing function | |

| Image reconstruction tact time | Within about 10 seconds |